What Is Onsite Equipment Mapping?

Onsite Equipment Mapping is critical to FacilityONE's facility management software onboarding process. Formerly known as Field implementation, this step in the onboarding process comes after a facility's floor plans or blueprints are transformed into F1 MAPS interactive maps, but before going live.

After your facility's floor plan or blueprints are transformed into digital interactive maps by FacilityONE, an experienced Onsite Equipment Mapping team member will travel to your facility. While onsite, they will canvas all levels of each building, including basements and roofs, to take pictures of each piece of equipment, including but not limited to mechanical, electrical, and plumbing assets. In addition to taking pictures of the equipment, the team also collects critical information like model and serial numbers.

How Long Does Onsite Equipment Mapping Take?

Each member of FacilityONE's onsite equipment mapping team can canvas, photograph, and document approximately 100,000 square feet of assets and equipment per day.

What are the Benefits of Onsite Equipment Mapping?

Choosing to have the Onsite Equipment Mapping team come onsite during the onboarding process provides significant benefits to your facility, including;

- Improved accuracy of equipment locations and information

- Increased knowledge of onsite equipment inventory

- Ability to easily share facility information with new team members

- Quicker response time during an emergency

- More informed budgeting and capital planning

- Enhanced asset management

What Happens After Onsite Equipment Mapping?

Equipment photos and information collected onsite are uploaded into your FacilityONE Solutions Suite and specifically into F1 MAPS, interactive mapping software. The images and data are mapped to their exact location in your facility. A digital equipment card is created for each piece of equipment and attached to it.

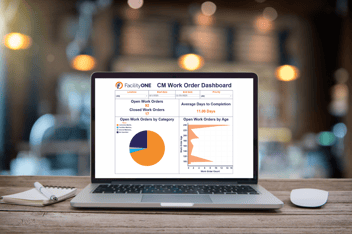

By clicking on a piece of equipment, facility managers and technicians can view existing information and add new information, like maintenance notes. Equipment can be viewed and edited from any smartphone, tablet, or computer connected to the internet. Managers and technicians can then easily search for equipment, attach work orders to the equipment, and run reports.

.png?width=268&height=52&name=f1-logo2%20(1).png)